Unlocking Industry 4.0 with VR and R3DT

Posted; December 30, 2019

Designing new production lines is an enormous undertaking, with months of planning and development. With Ultraleap’s technology and support, R3DT is accelerating this process with an easy-to-use tool that replaces physical prototyping with VR. In a recent deployment with a major automotive partner, they were able to unlock a 30% cost saving – and they’re just getting started.

Today’s industrial engineering prototypes are built with cardboard

Before an assembly line can be built, it must be designed. Many manufacturers use a process known as cardboard engineering to develop physical layouts. Setting up in empty factories, industrial engineers create entire assembly lines – out of cardboard.

Cardboard engineering allows for rapid iteration and prevents costly mistakes. But it’s still a cumbersome process.

Smart planning with VR prototypes

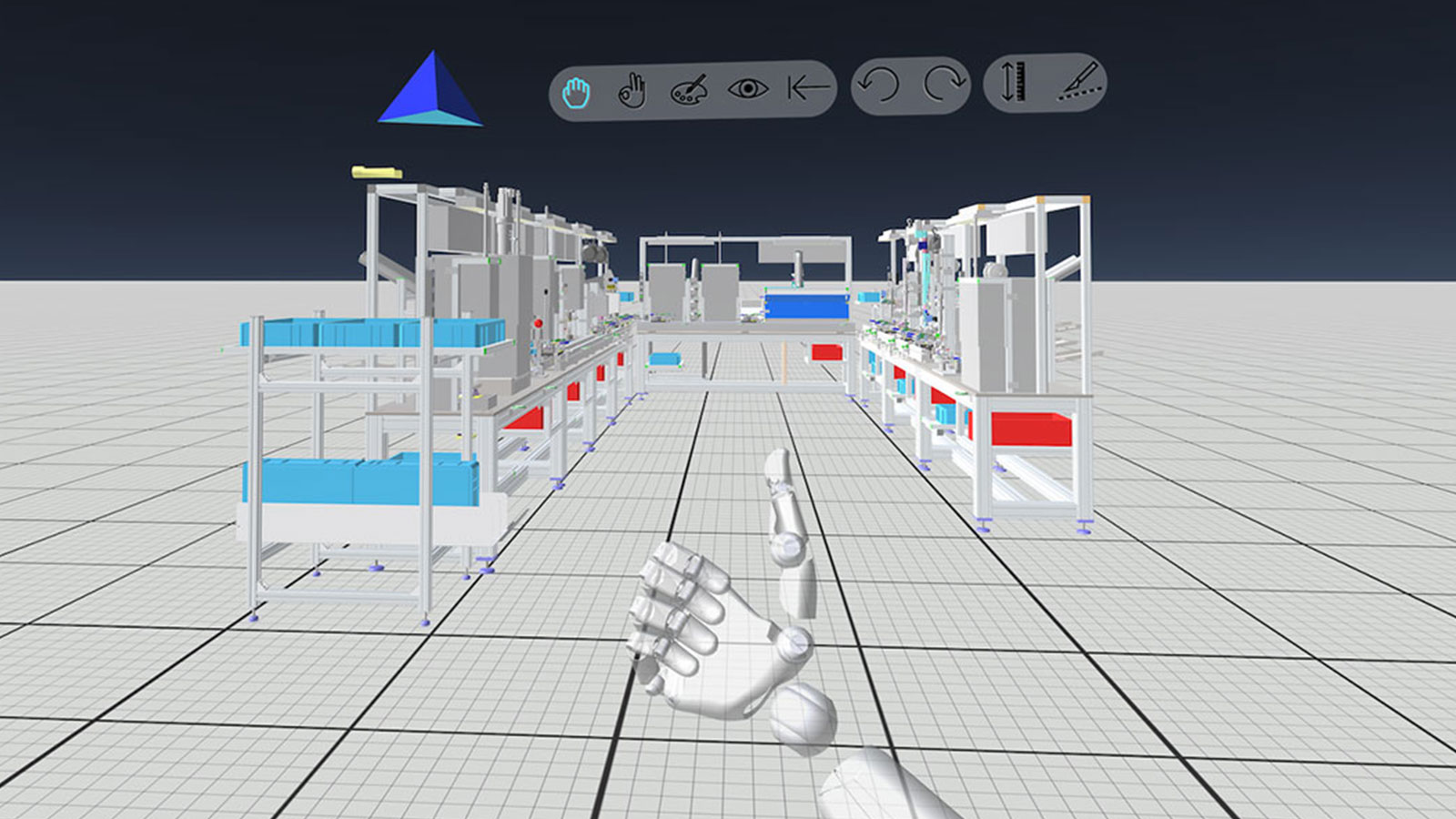

R3DT is a VR tool for industrial engineering, designed to be used throughout the entire assembly line planning process. This includes ergonomics, factory layout planning, assembly processes, special machinery and plant construction, technical purchasing, and sales.

During early planning, virtual prototypes make it possible for industrial engineers to avoid errors that might not be apparent in 2D. Hand tracking from Ultraleap makes interacting with 3D virtual prototypes easy and intuitive, without the need to learn buttons on handheld controllers.

Prototypes can be generated at the push of a button from 3D CAD data within a few minutes. Everyone involved in the development process can quickly and easily see the latest version of the space, making critical design reviews faster and easier.

R3DT currently has deployments with roughly 50 customers. One major automotive partner has R3DT’s VR solution deployed at seven European manufacturing facilities. Recently, they were able to save an average of 30% of costs on the prototyping phase, and shaved weeks off their deployment time.

The next major phase of development will focus on VR collaboration tools for industrial engineering. “Our customers have plants all over the world,” says Andreas Ruedenauer, “and R3DT will allow them to connect the different parts of their businesses one-on-one in ways that are impossible now.”

No matter how smart a factory is once up and running, it still needs to be designed by humans in the first place. R3DT are making this design process more intuitive and accessible – giving industrial engineers the tools they need to accelerate the path to Industry 4.0.