A future you can reach out and touch

Posted; November 2, 2022

Mid-air haptics - virtual, tactile sensations projected onto the hands – have opened up huge opportunities for the way we engage with technology. We have already demonstrated that the future is one focused on human technology and natural interaction. Today we set out what’s next on the journey.

Leaders in mid-air haptics

We create virtual touch. This means users can “feel” and interact with virtual objects and controls. Our unique algorithms and cutting-edge hardware project ultrasound-based tactile sensations in mid-air. This makes our hands the ultimate tool, removing the boundaries between physical and virtual environments, and enabling truly natural interaction.

At Ultraleap we’re proud to have led this transition, pioneering the use of mid-air haptics around the world. We’ve worked with some of the most innovative brands on the planet, introducing virtual touch in digital and real-world environments.

In automotive, DS Automobiles have implemented our technology to remove the need for touchscreens and physical buttons in their DS Aero Sport Lounge concept car for a maximum luxury look and feel.

Award-winning advertising agency Ocean Outdoor used our technology to create an immersive experience for LEGO’s Rebuild the World campaign. LEGO fans of all ages could virtually reach into a large-screen digital billboard to move, rotate, and feel LEGO bricks to build models.

We brought our ultrasonic touch to the big screen, working with the Aquarium of the Pacific to enable visitors to “feel” what’s happening on a screen while watching a film. We’ve even added a haptic dimension to mixed reality, helping visitors to “The Unreal Garden” experience at E3 to reach out and touch energy balls.

Driving continual innovation: smaller, cheaper, and automotive ready

Industry requirements and consumer expectations are constantly changing and we’re changing too. Our haptics teams have been hard at work developing the next generation of hardware, software, and tooling, and we’re excited to start sharing them.

Haptics Hardware

At Ultraleap we believe that human experiences should be powered by hands, not hardware – but this year we’ve achieved a hardware feat that stretches the laws of physics.

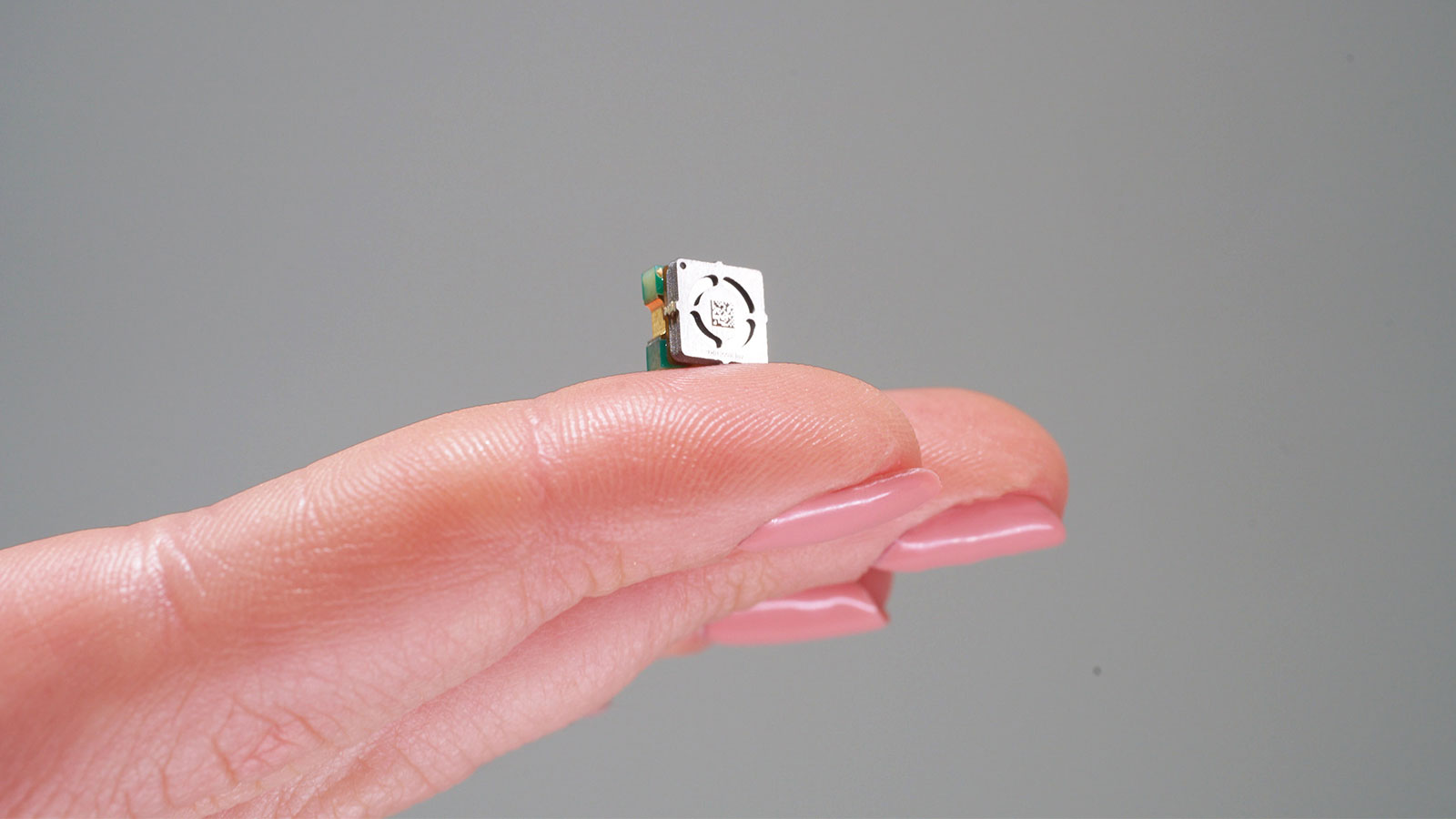

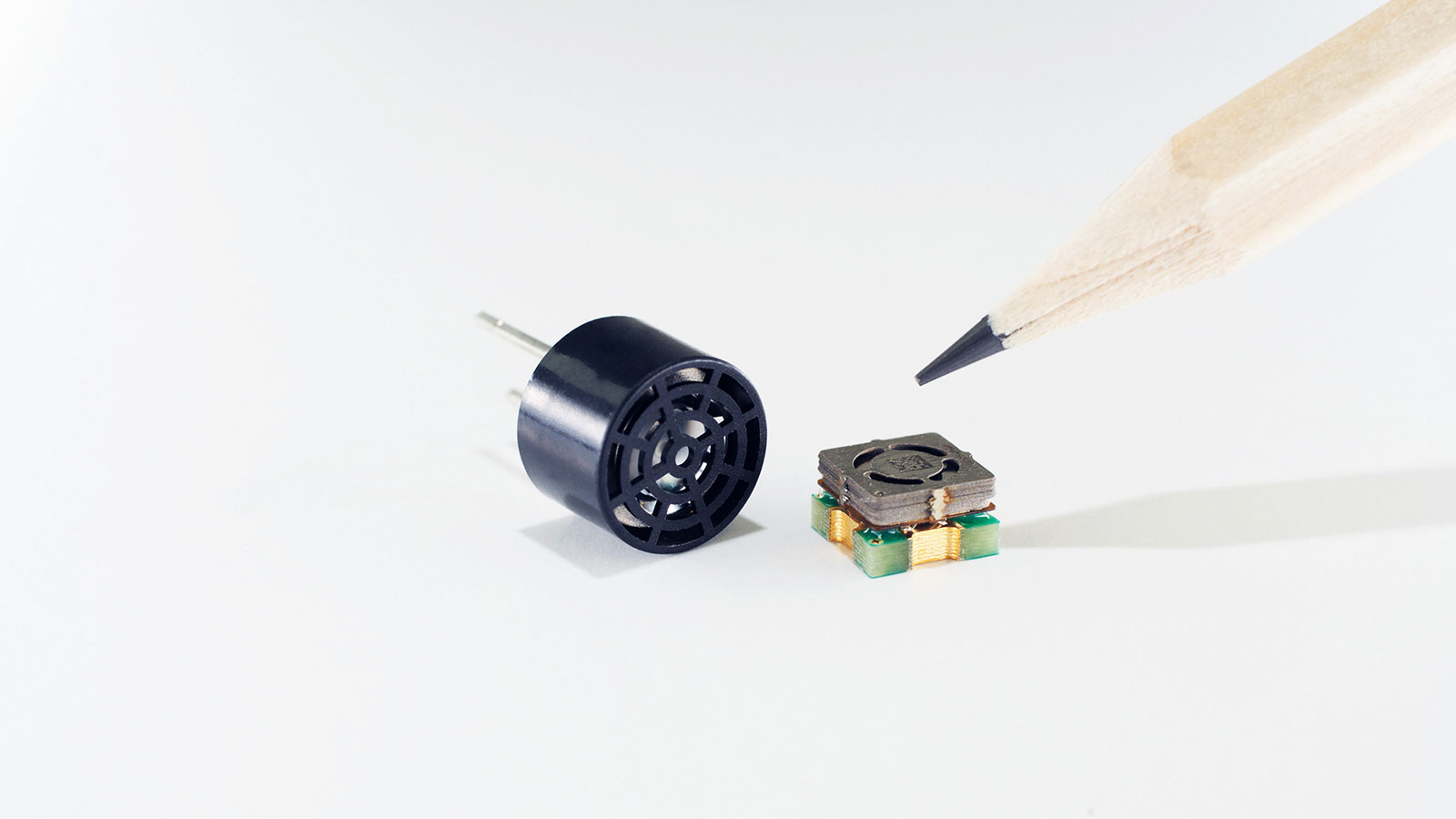

The physical size and cost of a mid-air haptics system has been the biggest blocker to large-scale adoption. The transducers, which project the ultrasound to create a haptic effect, are the biggest and most expensive component in this system. We have been on a mission for seven years to design and produce a better transducer, and I’m very proud to announce that we’ve succeeded.

We’ve now completed the development of our new transducer and moved into initial production. It is smaller, cheaper, and easier to build which means it can be manufactured at scale much more efficiently. It doesn’t compromise on performance and can be assembled into products by machines, not people. Typically, transducers with similar performance have a depth similar to the wavelength of the ultrasound being emitted, which defines the component size. Our engineers have managed to achieve target performance in a fraction of a wavelength, shrinking the component significantly and delivering all the associated benefits. This is significant for our customers because it will open the door to truly scalable production of mid-air haptics for the first time.

Importantly, the new transducer will be fully qualified for automotive use, meaning it can be used with confidence by automotive OEMs in their next generation of vehicles. The potential is huge.

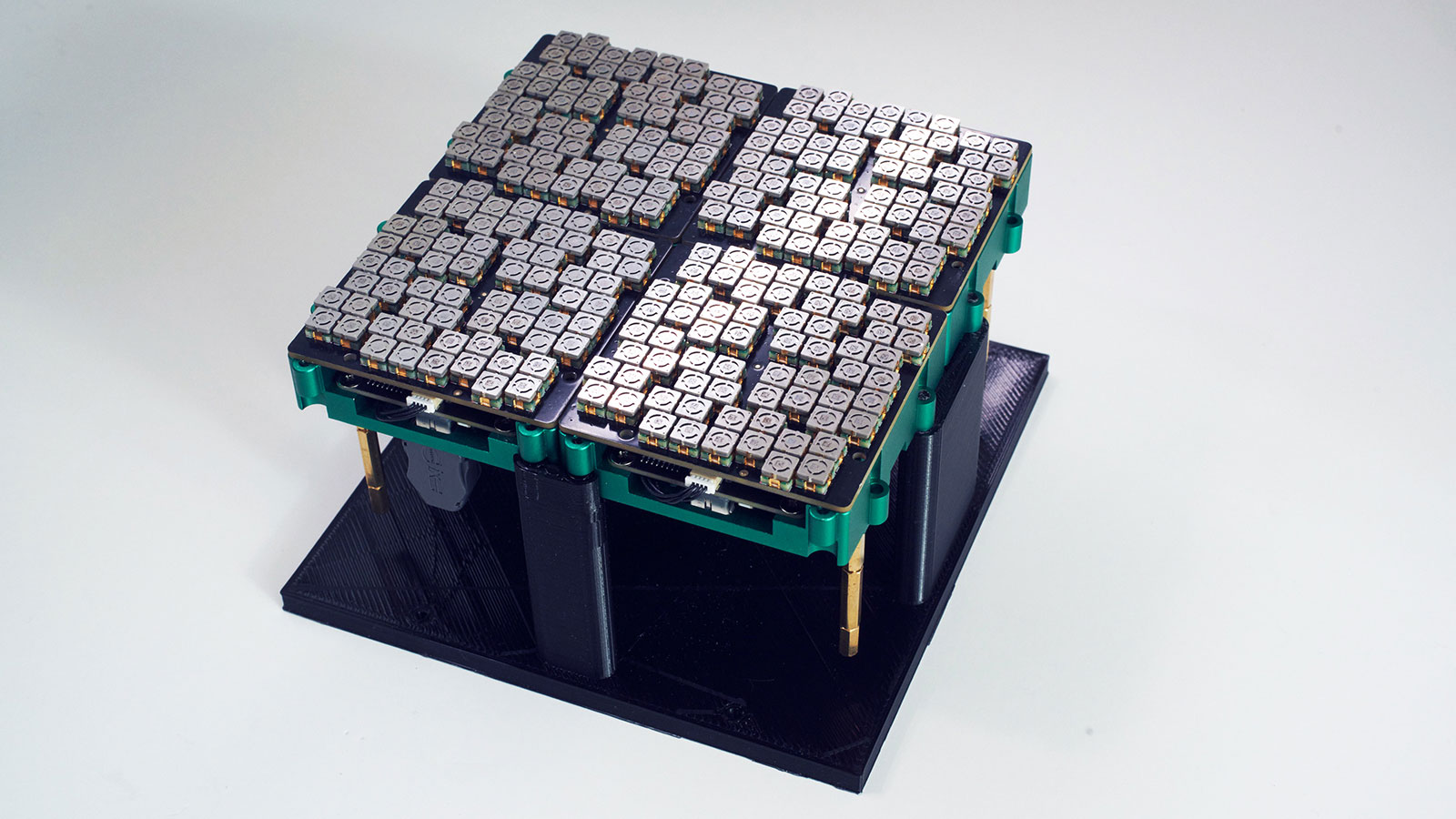

For our automotive customers, we’ve also integrated these ground-breaking transducers into a modular and flexible development platform. This kit enables them to evaluate and optimise their own specific use cases, in any layout and position within a vehicle. No costly rebuilds or bespoke hardware. This platform will accelerate the development time and reduce the cost of creating optimised interactions.

This has been a long journey for our world-class team of scientists, engineers, and manufacturing specialists. They have overcome many challenges along the way and have genuinely pushed the boundaries of what’s possible with this latest development.

Haptics software and tooling

Our new transducers make haptics smaller and cheaper to produce at scale, but it’s our software that makes it possible to amplify the mid-air haptic sensations. We’ve listened to our developer community and customers and have been working hard on the next iteration of our software.

Embedded sensations are one way we’ve innovated in this area. We have been able to reduce the compute requirements of our haptic technology by decoupling the haptic device from the computer – something that was previously essential in creating haptic sensations. The haptic device is now in control of generating the sensations. The result is a simple, low-bandwidth interface that enables low-compute haptics with significantly increased strength and consistency.

Get in touch

We are also building a range of new tools that will enable users to quickly develop and optimise haptic sensations for their specific interactions, without requiring coding experience. This means that R&D teams and UX/UI designers can explore the benefits of haptic technology without needing a specialist developer on hand. Users will be able to create haptics that directly correlate to an experience or feeling, or even to the brand itself.

These tools are currently available on request – please get in touch to find out more and discuss your requirements.

Retiring STRATOS

As a direct result of these advances in technology, we are sunsetting our STRATOS platform – the core of our haptic proposition since 2018. It’s been a real game changer, but we have now retired both the STRATOS Inspire and our development kit, the STRATOS Explore, to make way for our new innovations.

Where required for their needs, current customers will still be able to upgrade to our newer software and we will still provide support. However, we won’t be developing the STRATOS software further, focusing instead on the next generation of mid-air haptics products and solutions.

We’re encouraging STRATOS users to get in touch if they have any questions about this process, and of course, we’d love to speak to you about how we can help move you onto our new technologies and tools.

Accelerating automotive

The automotive industry was one of the first to embrace the potential of mid-air haptics. The benefits are clear. Using hand tracking and mid-air haptics to control your environment is safer because it keeps your eyes on the road, rather than a touchscreen. The intuitive nature of touch puts the driver in complete control and provides a better driving experience all round.

Over the last eight years, developers and research teams at many of the world’s biggest car manufacturers have been using our technology to research and test the potential for controlling virtual touch. While some automotive gesture control systems are already commercially available, the lack of tactile feedback has remained the missing piece of the puzzle, often causing frustrated users to “overshoot” or distract them away from the road ahead.

The recent technological developments at Ultraleap will enable the automotive industry to fully embrace the potential of mid-air haptics and move beyond concept cars into mainstream manufacture of the next generation of vehicles.

Looking to the future of the highly competitive world of car design, the in-cabin experience is more important than ever. The rise of electric cars is levelling the playing field for vehicle performance. Manufacturers can no longer rely on differentiating through outright power and are looking for alternative ways to separate them from the rest. Inside the car, user interfaces are increasingly dominated by the likes of Android Auto and Apple CarPlay, removing much of the design freedom and opportunity to differentiate enjoyed by automotive UI designers. In this context, outstanding user experience will be measured on the quality of the connection between people and their car.

Brands want to emotionally connect their users to their vehicles adding drama and theatre into things like the start-up experience. Imagine starting your car by raising your hand towards the centre console, feeling a laser-like sensation scan across your palm whilst the lights pulse and the vehicle comes to life around you. It’s the missing piece of the puzzle in the automotive HMI of the future and OEMs are embracing this to stand apart from the competition.

Our vision for virtual touch

In the future, anyone anywhere will be able to interact with digital content as fluently as they can interact with physical objects. Using our hands and being able to control, touch, and feel this content will be crucial.

The metaverse is perhaps an over-hyped term, but ultimately, it’s a useful way of describing a world in which digital content is predominantly 3D and blended into the physical world.

The metaverse will depend on more natural forms of interaction - enter hand tracking and mid-air haptics.

It’s the combination of our technologies that truly enable natural interactions, without the need for controllers, buttons, or touchscreens. This will tear down the boundaries between real and virtual experiences. It will help to create real emotional connections between people, products, and places, whether that’s driving, shopping, or at home, school or work.

The developments we’ve worked on are taking the magic potential of mid-air haptics and making it real, scalable, and affordable. Our brilliant community of developers have already been working on bringing some amazing designs into reality. We love working with our developer community and are inspired by their creativity and enthusiasm. Thank you for joining us on this journey.

This is our vision for mid-air haptics. Starting with automotive but driving into so many other corners of the world. Increased awareness of the importance and potential of haptics, combined with the latest technology and the enthusiasm from our developer community presents almost limitless opportunities to harness hands, not hardware, in everyday life. We can’t wait to see what happens next.

Get in touch to discuss these latest developments or to talk through your ideas. We’d love to find out how we can help.

Move beyond

Explore our blogs, whitepapers and case studies to find out more.